In the research recently done emphases on studying the Statistical Process Control tool with the aim to improve quality and cost effectiveness. In todayΓÇÖs era there is more competition in the market, there is only one rule survival for the fittest. The success of any company does not always depend on previous performance but it depends on current performance too. The only way to survive in the market is to always provide excellent product and provide more than expectation to the customer but at low price. In todayΓÇÖs scenario where the cost of resource and raw material is high, hence the cost of manufacturing is high, so decision makers must make the decision based on facts rather than following conventional way. There is need of continuous data collection and here in the stage we need to take the help of Statistical Process Control.

The companies in Zimbabwe are witnessing lack of ability to stand in the global competitive market. Here they need to deeply study and implement the tools of Statistical Process Control (SPC).

Statistical Process Unit is basically the application to statistical method for monitoring and controlling the process for assuring confirmed product. Under SPC a process behaves predictably so that accurate product is produced with less waste. There are various tools of SPC like control chart, continuous improvement and design experiment.

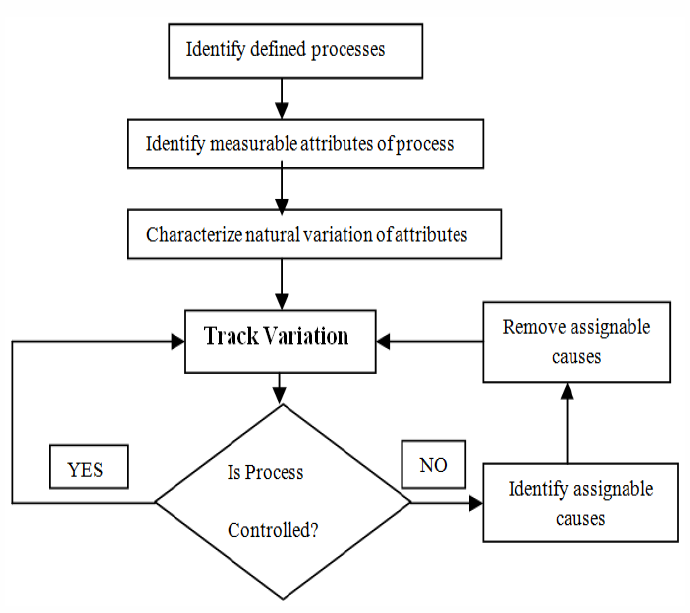

Variation or difference in the process that may affect the quality of the product will be deleted ensuring nil waste. On verifying an out of control process the engineers are alarmed and the process is re- evaluated.

In Statistical Process Unit, it is very necessary to understand and identify the key product characteristics which are critical to customers or key process variation.

The Pareto effect has to be used to identify the vital few processes, which control manufacturer and then building around the planning around these key processes and product for quality control activity.

In practice report of SPC in manufacturing tend to concentrate on a few processes. Thus SPC is used to control formal inspections, testing.

Methodology for SPC questionnaires, surveys were done by the companies from Zimbabwe to assess the level to which Statistical Process Unit was used in the company, it was also done to see whether spc can be implemented in the company.

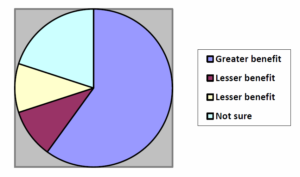

After the survey 80 percent of the staff wanted Statistical process unit to be implemented whether 20 percent were not sure, the internal public understood that SPC is very necessary to match the competitor and cut off extra cost in manufacturing.

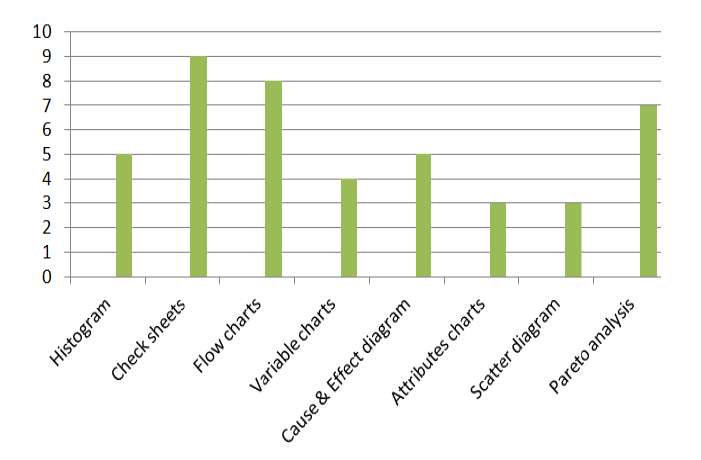

Extent of usage SPC tools

It was evident from the results that most popular tools in the industry were check sheets and flowchart respectively followed by Pareto Analysis. The other five SPC tools did not have significant application as given.

It was found that design of experiment was the least technique, although it is one of the advanced techniques helpful in identifying problem. The main Benefit of SPC is that it improves understanding between employee and process.

But there are many challenges while implementing the first of all the employees needed to be well trained about the tools and techniques.

Although the companies are known that and Pareto analysis should be used before to know the issue, the other charts like histogram and cause effect theory need to be relooked.

Checkout the details of our SPC Software for Manufacturing